Kupanga margarine kumaphatikizapo magawo awiri: kukonza zopangira ndi kuziziritsa ndi kuyika pulasitiki. Zida zazikuluzikulu zikuphatikiza akasinja okonzekera, pampu ya HP, votator (yowotcha pamtunda), makina owongolera apini, firiji, makina odzaza margarine ndi zina.

Njira yakale ndi kusakaniza kwa gawo la mafuta ndi gawo la madzi, kuyeza ndi kusakaniza kwa emulsification ya gawo la mafuta ndi gawo la madzi, kuti akonzekere kudyetsa zinthu zomaliza. Njira yomaliza ndi kuzizira kosalekeza plasticizing ndi ma CD mankhwala.

Njira yokonzekera margarine yaiwisi ikuwonetsedwa mu Chithunzi 1:

1.Mkaka wofufumitsa

Ena margarine chilinganizo kuwonjezera mkaka, ndi mkaka pambuyo lactic asidi mabakiteriya nayonso mphamvu akhoza kupanga ofanana kukoma zachilengedwe zonona, kotero fakitale kuti thovu mkaka ndi madzi wothira.

2.Kusakaniza madzi

The madzi ndi madzi sungunuka zina mu chilinganizo cha margarine, monga thovu mkaka, mchere, zotetezera, etc., ndi anawonjezera madzi gawo kusanganikirana ndi metering thanki mu mlingo analamula kusonkhezera ndi kusakaniza, kuti gawo madzi. zigawo zikuluzikulu zimasungunuka mu njira yofanana.

3.Kusakaniza gawo la mafuta

Mafuta aawisi amitundu yosiyanasiyana amayamba kusanganikirana mu thanki yosakaniza mafuta molingana ndi kuchuluka kwake, kenako zowonjezera zosungunuka zamafuta, monga emulsifier, antioxidant, pigment-soluble pigment, cellulose sungunuka wamafuta, ndi zina zambiri. gawo la mafuta molingana ndi gawo, losakanizidwa ndi tanki ya metering, ndikusonkhezera kupanga gawo limodzi lamafuta.

4. The emulsion

The emulsification cholinga margarine ndi kupanga amadzimadzi gawo wogawana ndi stably omwazika mu gawo mafuta, ndi kubalalitsidwa digiri ya gawo amadzimadzi zimakhudza kwambiri khalidwe la mankhwala. Chifukwa kukoma kwa margarine kumagwirizana kwambiri ndi kukula kwa tinthu tating'onoting'ono tamadzi, kufalikira kwa tizilombo tating'onoting'ono kumachitika mu gawo lamadzi, kukula kwa mabakiteriya ambiri ndi 1-5 ma microns, kotero madontho amadzi mu 10-20. ma microns kapena ang'onoang'ono osiyanasiyana amatha kuchepetsa kufalikira kwa mabakiteriya, kotero kuti kubalalitsidwa kwa gawo la madzi kuli bwino kwambiri, tinthu tating'onoting'ono tamadzi timapangitsa margarine kutaya kukoma; Kubalalitsa sikokwanira, madzi gawo tinthu ndi lalikulu kwambiri, adzapanga margarine chinyengo metamorphism. Ubale pakati pa kuchuluka kwa gawo lamadzimadzi lomwazika mu margarine ndi mtundu wa chinthucho ndi pafupifupi motere:

| Madontho a madzi (micrometer) | Kukoma kwa Margarine |

| zosakwana 1 (pafupifupi 80-85% ya gawo lamadzi) | Zolemera ndi zochepa kukoma |

| 30-40 (osakwana 1% ya gawo lamadzi) | Kukoma kwabwino, kosavuta kuonda |

| 1-5 (pafupifupi 95% ya gawo lamadzi) | Kukoma kwabwino, sikophweka kubvunda |

| 5-10 (pafupifupi 4% ya gawo la madzi) | |

| 10-20 (pafupifupi 1% ya gawo lamadzi) |

Zitha kuwoneka kuti ntchito ya emulsification iyenera kufika pamlingo wina wa zofunikira zobalalika.

Cholinga cha kusakaniza gawo la madzi ndi gawo la mafuta padera komanso mofanana ndi gawo lapitalo ndikuonetsetsa kuti yunifolomu ikugwirizana ndi emulsion yonse pambuyo pa emulsification ndi kusakaniza mafuta ndi madzi magawo awiri. Kusakaniza kwa emulsification ndiko, vuto la opaleshoni ndi madigiri a 50-60, gawo lamadzi limawonjezedwa ku gawo la mafuta, mu makina oyendetsa kapena kupopera mkombero woyambitsa, ndiye gawo lamadzi lobalalika kwathunthu mu gawo la mafuta, mapangidwe a latex. Koma mtundu uwu wa lalabala madzi ndi wosakhazikika, kusiya oyambitsa angakhale pa malo osewerera mafuta ndi madzi kulekana chodabwitsa.

Pambuyo pa emulsion yosakanikirana imaperekedwa, njira yoziziritsa ndi pulasitiki ikuchitika mpaka mankhwalawo atayikidwa.

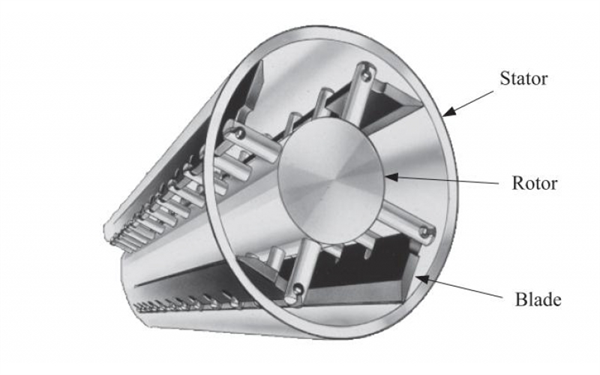

The emulsion ayenera utakhazikika ndi pulasitiki kupanga chosinthika margarine mankhwala. Pakali pano, makamaka utenga chatsekedwa mosalekeza kuzimitsa plasticizing chipangizo, kuphatikizapo voti kapena chotchedwa scraped pamwamba kutentha exchanger (unit A), pini rotor makina kapena kneading makina (gawo C) ndi kupuma chubu (unit B). Njira yaukadaulo ikuwonetsedwa mu Chithunzi 2:

Zidazi zili ndi izi:

1. Kuthamanga kwambiri kwa mpweya wopitirirabe kugwira ntchito

The premixed emulsion amadyetsedwa mu yamphamvu kuzimitsa ndi mkulu kuthamanga mpope kwa voti. Kuthamanga kwakukulu kumatha kugonjetsa kukana mu unit yonse, kuwonjezera pa ntchito yothamanga kwambiri kungapangitse kuti mankhwalawa akhale ochepa komanso osalala. Kutsekedwa ntchito kungalepheretse mpweya ndi mpweya chifukwa quenching ndi condensation madzi wothira emulsion, kuonetsetsa mankhwala zofunika thanzi, kuchepetsa imfa ya firiji.

2. Kuzimitsa ndi emulsification

The emulsion kuzimitsidwa ndi ammonia kapena Freon mu voti kuziziritsa emulsion mofulumira, kuti kupanga ang'onoang'ono crystalline particles, zambiri 1-5 microns, kotero kuti kukoma wosakhwima. Kuphatikiza apo, scraper pa shaft yozungulira mu votator imagwirizana kwambiri ndi khoma lamkati la silinda, kotero kuti scraper ikugwira ntchito sikuti imangokhalira kupukuta crystallization yomwe ikugwirizana ndi khoma lamkati, komanso kupanga emulsion omwazika kukakumana ndi emulsification zofunikira za kamvekedwe.

3. Kukandira ndi kufewetsa (makina a pin rotor)

Ngakhale emulsion utakhazikika ndi voti wayamba kubala crystallization, ayenera kukula kwa nthawi. Ngati emulsion amaloledwa crystallize pa mpumulo, maukonde olimba zamadzimadzi makhiristo adzapanga. Chotsatira chake ndi chakuti emulsion yokhazikika idzapanga misa yolimba kwambiri yopanda pulasitiki. Choncho, kuti apeze mankhwala margarine ndi plasticity ena, dongosolo maukonde ayenera kuthyoledwa ndi mawotchi njira pamaso emulsion kupanga lonse maukonde dongosolo, kuti tikwaniritse zotsatira kuchepetsa thickening. Kneading ndi de-thickening imachitika makamaka mu makina a pini rotor.

Unit A (voteta) kwenikweni ndi chipangizo chozizirirapo. The emulsion imayendetsedwa mu chatsekedwa unit A (voti) ndi mkulu-anzanu mpope. Zomwe zimadutsa mumsewu pakati pa silinda yozizira ndi shaft yozungulira, ndipo kutentha kwa zinthu kumatsika mofulumira ndi kuzimitsidwa kwa sing'anga yozizira. Mizere iwiri ya scrapers imakonzedwa pamwamba pa shaft. Makhiristo omwe amapangidwa pakatikati pa voti amachotsedwa ndi scraper yothamanga kwambiri kuti nthawi zonse aziwonetsa malo atsopano ozizira komanso kusunga kutentha kwabwino. The emulsion akhoza kumwazikana pansi zochita za scraper. Zinthuzo zikadutsa mugawo A (votera), kutentha kumatsika mpaka madigiri 10-20, omwe ndi otsika kuposa mafuta osungunuka. Ngakhale kuti mafutawo ayamba kunyezimira, sanapangebe kukhala olimba. Panthawi imeneyi, emulsion ili m'malo ozizira ndipo ndimadzimadzi ambiri.

Mzere wozungulira wa unit A (voteta) ulibe kanthu. Panthawi yogwira ntchito, madzi otentha a madigiri 50-60 amatsanuliridwa pakati pa olamulira ozungulira kuti ateteze crystallization yomangidwa ndikuchiritsidwa pa olamulira ndikuyambitsa kutsekeka.

Chipangizo C (makina opindika a pini) ndi chipangizo chopondera ndikuchotsa, monga momwe tawonera pamwambapa. Mizere iwiri yazitsulo zazitsulo zimayikidwa pazitsulo zozungulira, ndipo mzere wazitsulo zokhazikika zimayikidwa pakhoma lamkati la silinda, zomwe zimagwedezeka ndi zitsulo zachitsulo pamtengowo ndipo sizikhudzana. Mtsinjewo ukazungulira pa liwiro lalikulu, zitsulo zachitsulo pamtengowo zimadutsa malire azitsulo zokhazikika, ndipo zinthuzo zimaphwanyidwa bwino. Pansi pa izi, zimatha kulimbikitsa kukula kwa makhiristo, kuwononga mawonekedwe amtundu wa kristalo, kupanga makhiristo osapitilira, kuchepetsa kusasinthika, ndikuwonjezera pulasitiki.

Unit C (makina a pin rotor) amangokhalira kukankha mwamphamvu usiku wozizira kwambiri, motero amangofunika kuteteza kutentha ndipo safuna kuziziritsa. Pamene kutentha kwa crystallization kumatulutsidwa (pafupifupi 50KCAL/KG), ndi kutentha kopangidwa ndi kukangana kokanda, kutentha kwa unit C (pini rotor macjhine) ndipamwamba kuposa kutentha kwa chakudya. Panthawiyi, crystallization ili pafupi 70% yathunthu, koma imakhala yofewa. Chomaliza chimatulutsidwa kudzera mu valve extrusion, ndipo idzakhala yovuta pakapita nthawi.

Margarine ikatumizidwa kuchokera ku C unit (makina a pini rotor), iyenera kutenthedwa pa kutentha kwina. Nthawi zambiri, mankhwalawa amayikidwa pa kutentha kwa madigiri 10 pansi pa malo osungunuka kwa maola oposa 48. Mankhwalawa amatchedwa kucha. Chophikacho chikhoza kutumizidwa mwachindunji kumalo opangira chakudya kuti agwiritse ntchito.

Nthawi yotumiza: Oct-14-2022